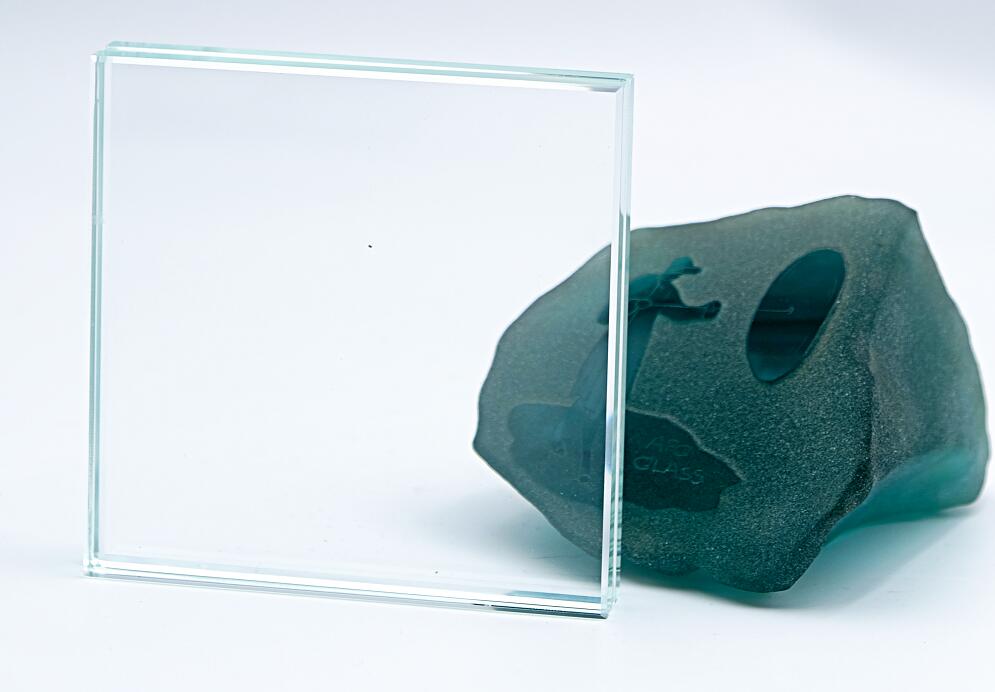

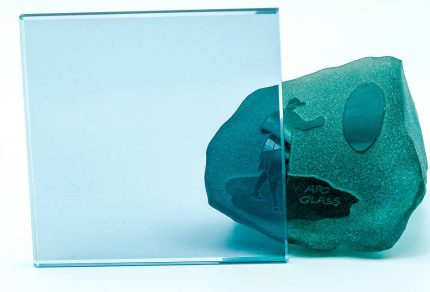

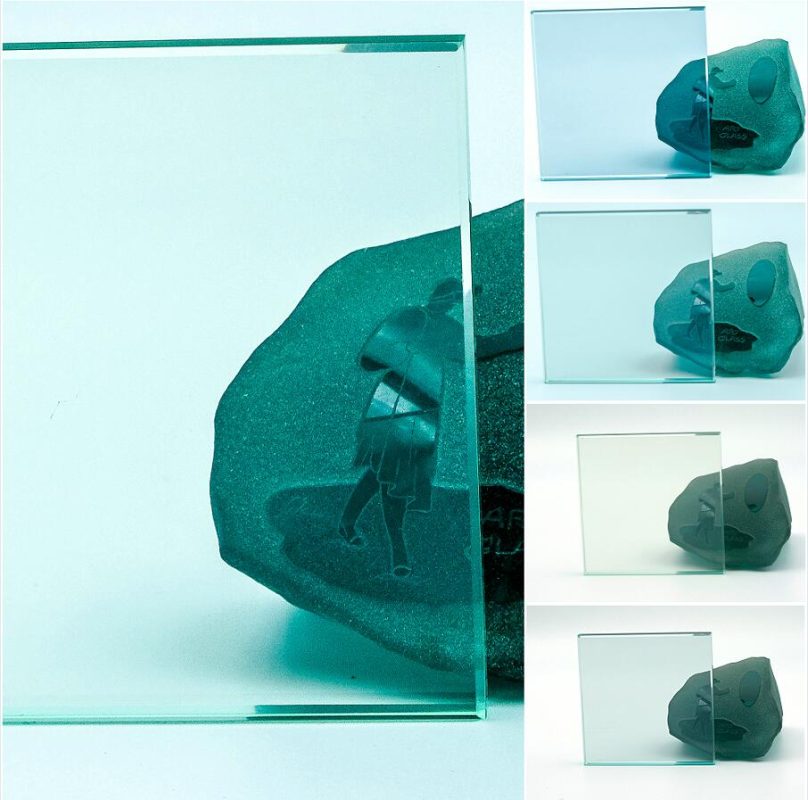

Durable Protection with Enhanced Clarity

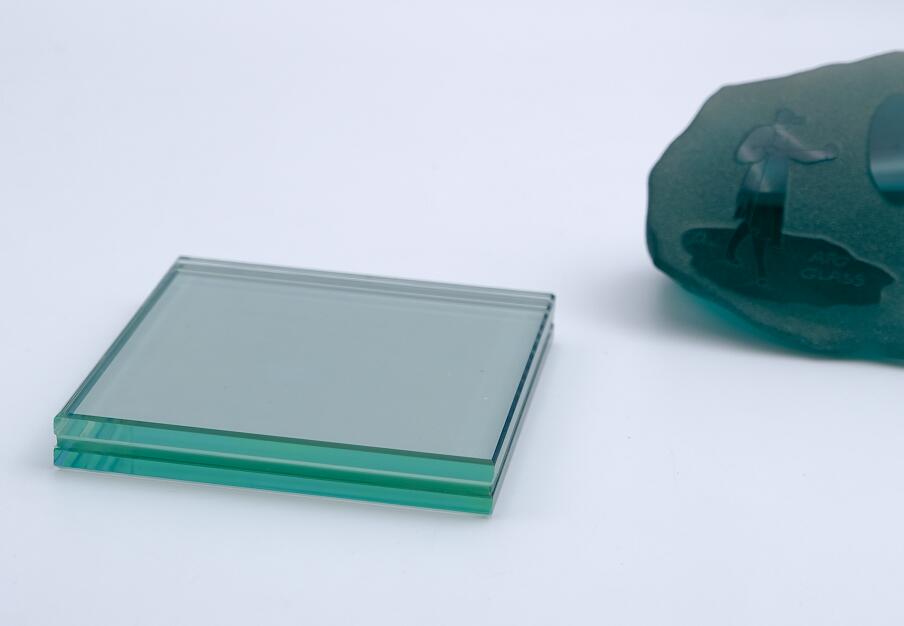

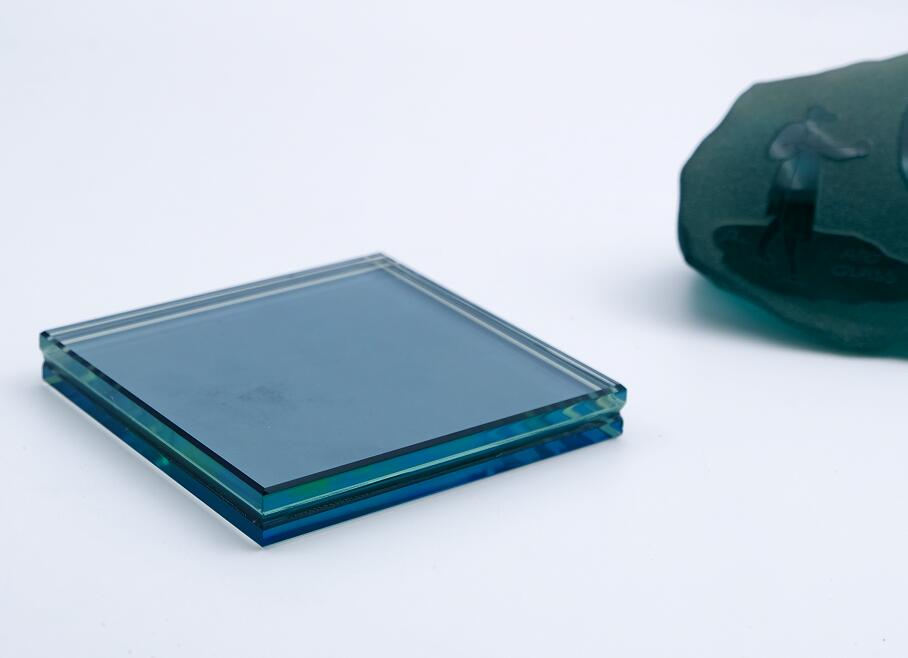

Laminated hard coated glass is commonly used in a variety of applications, including architectural and automotive glazing, as well as in the manufacturing of solar panels and other high-tech products. In architectural applications, laminated hard coated glass is often used for its aesthetic appeal and its ability to provide enhanced safety and security. In automotive applications, it is used for its ability to reduce glare and improve visibility, as well as its durability and resistance to impact.

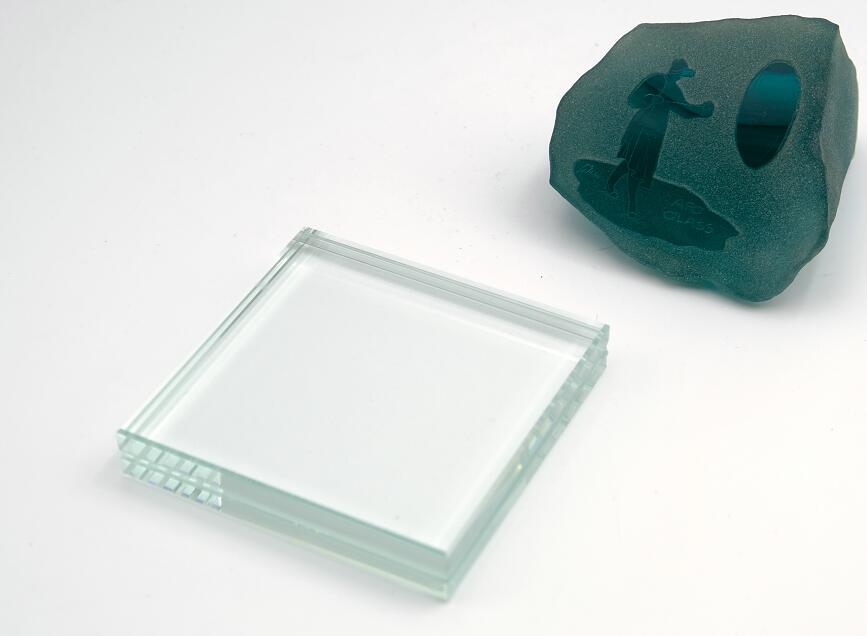

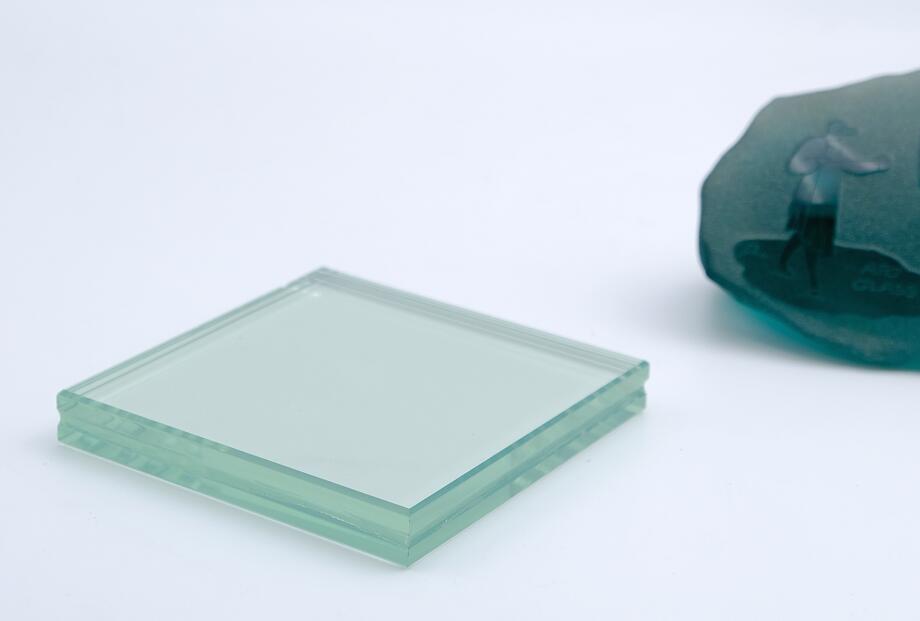

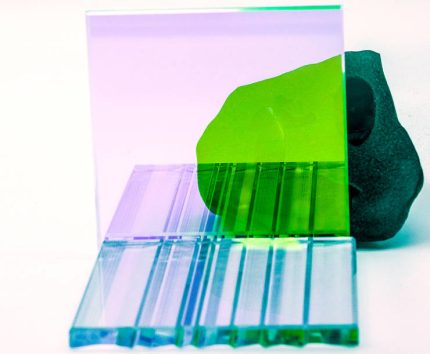

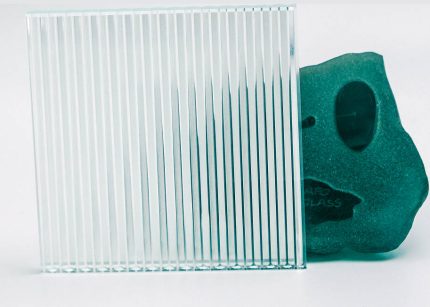

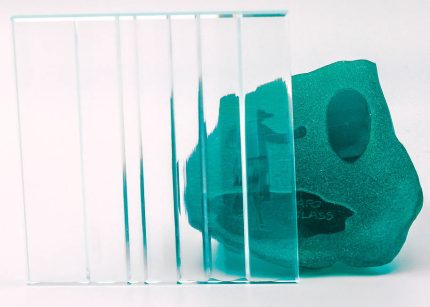

The process of producing laminated hard coated glass involves several steps. First, the glass is cut to the desired size and shape. Then, one or both sides of the glass are coated with a thin layer of hard coating material using a vacuum deposition process. The coated glass is then laminated with one or more layers of PVB (polyvinyl butyral) or EVA (ethylene-vinyl acetate) film, which acts as an interlayer to hold the glass together in the event of breakage. The laminated glass is then tempered or toughened to enhance its durability and safety.

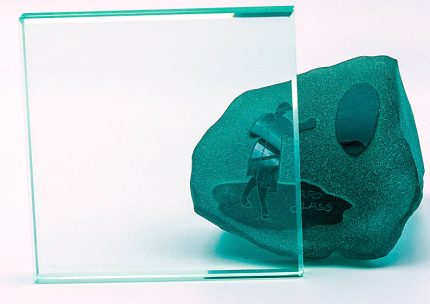

Laminated hard coated glass offers several advantages over traditional laminated glass. The hard coating provides improved surface hardness and durability, reducing the risk of scratching and chipping. The coating also reduces surface reflectivity, improving visibility and reducing glare. Additionally, the hard coating can be customized to provide a range of other benefits, such as improved thermal insulation or enhanced UV protection.

In conclusion, laminated hard coated glass is a versatile and high-performance product that offers a range of benefits for a variety of applications. Its combination of aesthetics, safety, and performance make it a popular choice for architectural and automotive glazing, as well as for the manufacturing of high-tech products. With its unique properties and advanced manufacturing techniques, laminated hard coated glass is a true breakthrough in glass processing technology.

HARD COATED GLASS HAS SEVERAL ADVANTAGES